VENTBUSTER Instruments

Monitoring emissions from abandoned wellsFrom an Idea to Fleet of Industrial Instruments

Capped oil and gas wells present a serious environmental and regulatory issue for Western Canada: despite rigorous capping and reclamation procedures, many of these wells continue to expel gasses into the atmosphere. Monitoring the rate of emission from these wells is an ongoing, unrelenting effort that requires a technician periodically travelling to the well-site and measuring the rate of flow using primitive methods. Ventbuster Consulting, an Alberta based company specializing in well-site abandonment and remediation proposed a device that would optimize and improve the collection of data from these wells so that it could be done remotely and report both flow rate and gas composition.

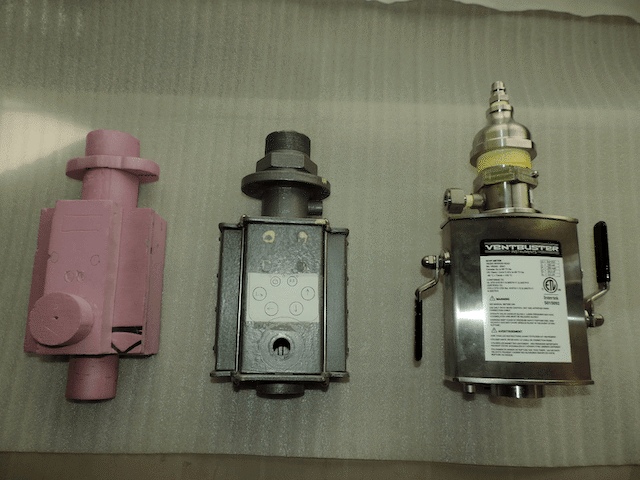

The client approached Tangent with a novel question: could an IOT style device be made that could measure consistent or intermittent low gas flow rates, on the order of one ‘bubble’ in ten minutes – and could the same device measure high flow rates and shut-in pressures? To further complicate the challenge, the device would need to be intrinsically safe, and rated for use in explosive atmospheric zones, and robust enough for use on site in the Oil and Gas industry. Ventbuster consulting had an exceptional understanding of the regulatory landscape surrounding capped wells and an acute awareness of the market need, but was without a research development team of their own to develop this project.

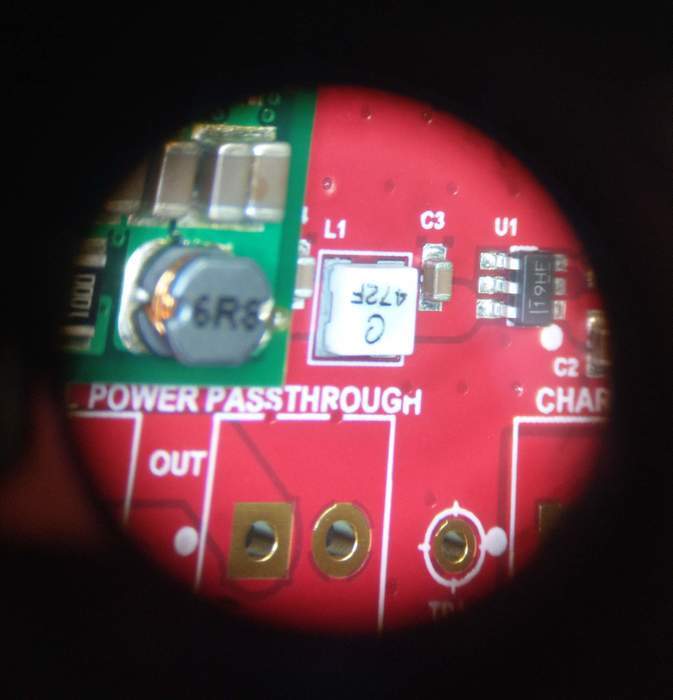

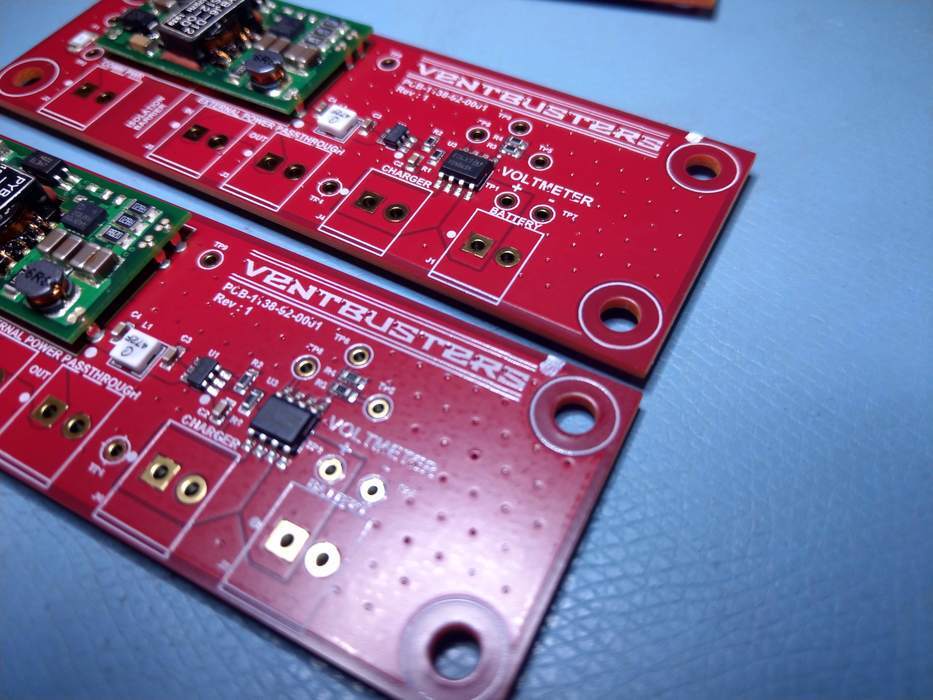

Tangent’s interdisciplinary project team set to work first developing a proof of concept prototype – ultimately developing a new sensor technology using Microelectromechanical (or MEMS) devices to detect extremely low flow rates. Once the concept had been demonstrated and proven with sufficient rigour, Tangent set about to develop this new sensor technology into a device that would comprise a fleet of instruments intended to wirelessly monitor capped wells in the field.

The development of this instrument employed the full spectrum of in-house expertise, from mechanical and electrical engineering to software/firmware development, user experience and industrial design through to manufacturing, compliance, testing and calibration. The availability of this broad base of expertise was critical to the success of the project, as each discipline was available to be consulted in-house at any point in the project, and the project passed seamlessly through Tangent’s product development process.

The result of our combined efforts was the VENTBUSTER®, a patented breakthrough in ultra low flow gas measurement designed for surface casing vent flow. In addition to detecting flow rates, the device measures gas composition and can autonomously conduct a test of the shut in pressure for the well. Once installed, the VENTBUSTER does not require technician to be present on site, allowing the same individual to test numerous wells in the time previously taken for a single measurement. The device wirelessly reports flow measurements and composition both to the technician and to an online dashboard, providing reports to operators and managers located at a central office